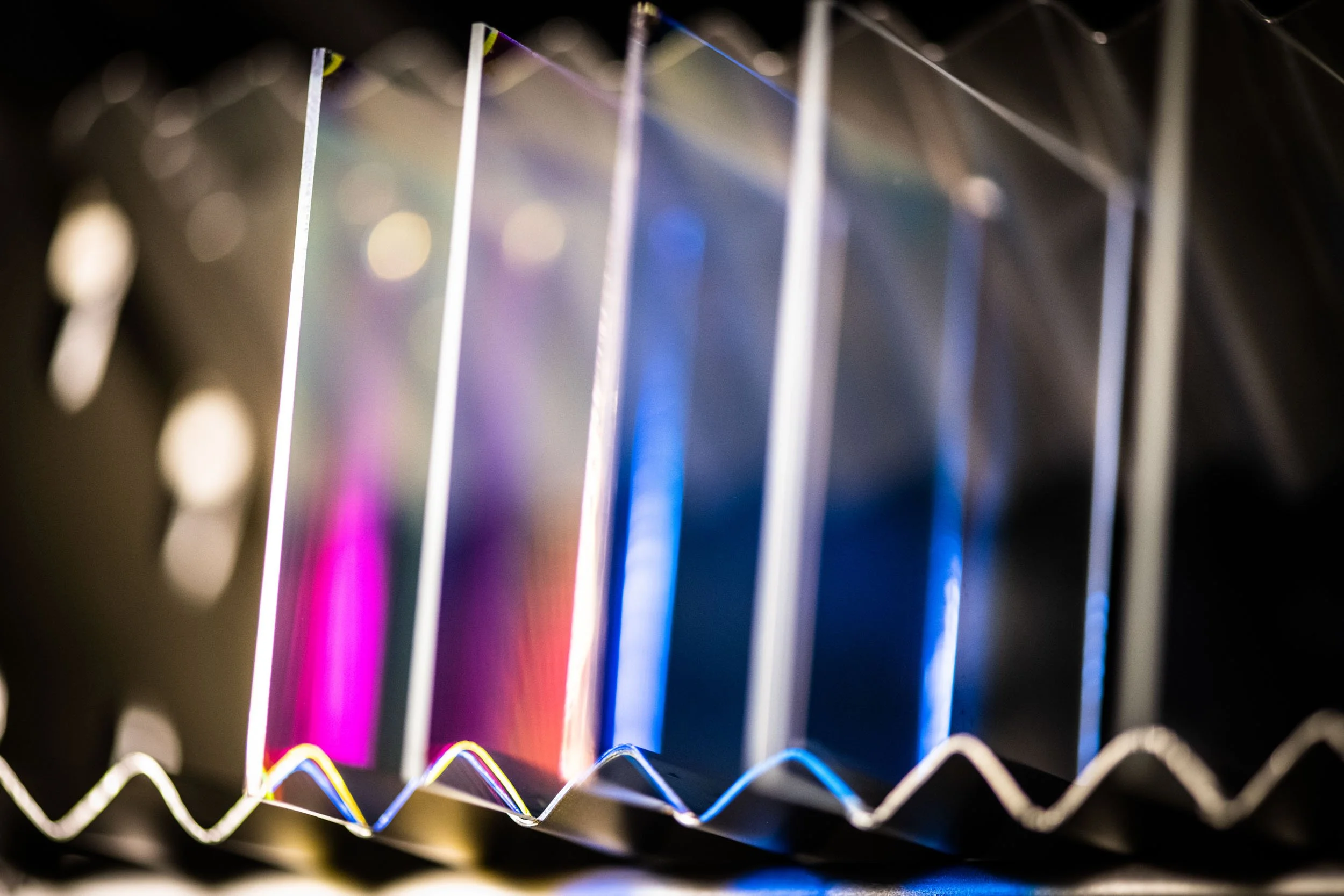

What Are Thin Film Optical Coatings?

Thin film optical coatings are specialised materials used in a range of applications, including aerospace, defence, healthcare, science, and satellite technology.

These coatings are made up of thin layers of materials that are applied to optical surfaces, such as lenses, mirrors, and windows, to modify the way light interacts with them.

View Our Range of Coatings:

In aerospace applications, thin film optical coatings are used to improve the performance of optical surfaces in harsh environmental conditions. For example, anti-reflective coatings are used on satellite and telescope lenses to minimize reflections and improve clarity, while colour filters are used to selectively transmit or block certain wavelengths of light for specific applications.

In defence applications, thin film optical coatings can be used to enhance the stealth capabilities of military vehicles, by reducing their reflectivity and making them more difficult to detect. They can also be used to protect sensitive equipment from damage due to environmental factors such as radiation.

In healthcare applications, thin film optical coatings are used in medical devices such as endoscopes and microscopes to improve image quality and enhance diagnostic accuracy. They can also be used to reduce the reflectivity of eyeglass lenses, improving comfort and visual acuity for wearers.

Discover More Capabilities:

In scientific applications, thin film optical coatings are used in a wide range of research instruments, such as spectrometers, interferometers, and detectors. These coatings help to improve the sensitivity and accuracy of measurements, and can also be used to control the polarisation and phase of light for specific experiments.

In satellite technology applications, thin film optical coatings are used in solar cells and satellite lenses to improve efficiency and durability in space environments. They can also be used to reduce the reflectivity of satellite surfaces, reducing the risk of interference with other satellites and space debris.

Thin film optical coatings are critical for improving the performance of optical surfaces in a wide range of applications. They can improve visibility, enhance image quality, reduce reflectivity, and enhance durability, all of which contribute to improved performance and reliability.

Visible/NIR Coatings

Eye Safe Laser Protection Filter

Military (including supply of filters to MIL-DTL-62422-AT)

Ophthalmic (including Colour-Corrected coatings)

Single & Dual Element Head-Up Display (HUD)

Colour-Selective Notch (Wavelength graded)

Colour-Selective Notch (Amplitude graded)

Neutral Density

Helmet Mounted Display (HMD) & Augmented Reality

Colour-Selective Notch

Neutral Density

Anti-Reflection (AR)

High Efficiency

Broadband

Multi-Spectral

Steep Edge Filter

Beamsplitter

Polarising

Neutral Density

Mirror

Enhanced & Protected Metal

Transparent Conductive Coating

De-misting/De-fogging/De-icing

EMI/RFI Shielding

High LIDT

Hydrophobic

Our Coatings

IR Coatings

Anti-Reflection (AR)

High Efficiency

High Durability

Electro-Optical Protection Measures (EOPM)

Narrow Bandpass Filter

Edge Filter

Beamsplitter

High LIDT

IR Coating Highlights

Successfully deposited ZnS/YF3/HFO2 onto ZnS with coating remaining spectrally compliant and surviving adhesion and abrasion tests after being subjected up to 600hrs in 95% RH @ 55°C Environment.

Numerous IR coatings which surpass usual requirements and demanding fast pull adhesion tests.

Successfully deposited numerous high-performing coatings which surpass customer requirements on a variety of substrate materials.

In 2022, we invested in our IR sector by engaging with IR specialist consultants to help validate our processes.